Notching machines of the INDUMASCH brand

More InformationNote: Indumasch notching machines have not been produced since 2023. Since then, we have continued to supply our customers with notching machines with spare parts and carry out repairs as required.

The notching machine from Indumasch is an economical solution that can be customised to meet individual company requirements. Machine technology specialists with many years of experience take care of product development and production at the Siegen-based company. The Indumasch notching machine is available in different versions, with a fixed or variable notching angle and with many additional features.

Modern sheet metal processing with notching machines from Indumasch

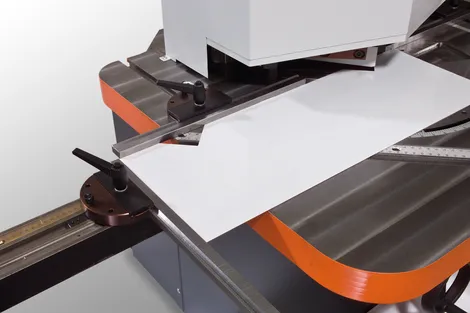

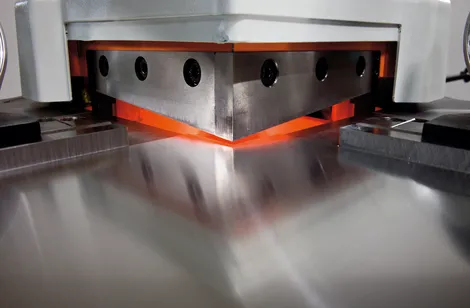

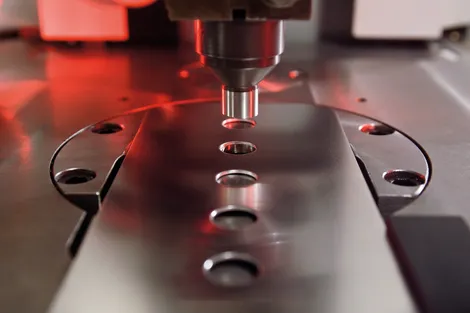

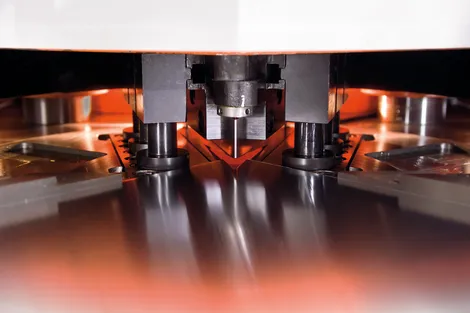

The notching machine models SAF 204 and SAF 206, for example, are particularly space-saving, have an automatic cutting gap adjustment, super measuring tapes with three reading functions and a fixed notching angle of 90 degrees. The notching machine model SAV 206 offers split upper and lower knives and a continuously variable notching angle of 30 to 140 degrees. The knives are clamped mechanically/hydraulically and secured against unintentional lifting. Each notching is carried out in a single operation. The Indumasch notching machine can even be used to work according to scribing and templates. The notching machine model DAV enables 30-140 degree notching and has super measuring tapes with five reading functions. Another advantage is the internal stop for cutting sheet metal strips to length. For bending, cutting and punching, Indumasch provides an excellent tool with a second station with digital stroke adjustment and a quick-change tool system. Every Indumasch notching machine enables clean cuts to be made without a shoulder, even beyond the blade length.

Perfect service around the notching machine

At Indumasch, you not only receive an innovative notching machine for modern sheet metal processing, but also competent training from experienced specialists on request. The team at the machine technology specialist from Siegen is also on hand to provide you with reliable support for all questions relating to maintenance and operation. Our own spare parts warehouse guarantees that your notching machine will be up and running again in the shortest possible time in the event of a breakdown. Indumasch develops customised tools for specific applications based on years of experience.

Video: Indumasch notching technology

Notching machine and application training courses

The decision in favour of an INDUMASCH machine is a decision in favour of state-of-the-art technology and high quality.

To ensure that all the advantages and technical possibilities of the notching machines can be utilised quickly and to their full extent, the operators are trained to become real experts within a very short time as part of professional training courses - so nothing stands in the way of efficient work with optimum production results!

Both in-house training courses, which are carried out directly on the new machine, and training courses in the INDUMASCH test workshop can be organised. The latter is ideal for training employees in advance so that they are already familiar with the INDUMASCH solution on the day of commissioning.

IMPORTANT for existing customers: New projects or staff changes mean a lack/loss of KNOW-HOW. This costs productivity and efficiency is lost. Production results leave a lot to be desired. DON'T LET IT GET THIS FAR. Request a free and non-binding retraining offer for your employees now. Our bending experts will keep you up to date.