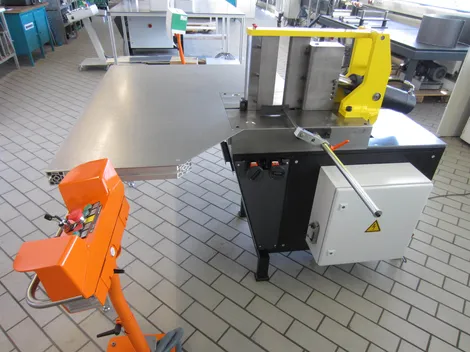

Press bending machine MINIBEND

More Information- Home

- Products

- Universal bending machines

- MINIBEND

Our bending press is a horizontal press. It is manufactured with tight tolerances and therefore achieves maximum reproducibility. The positioning accuracy is between ±0.03 mm and ±0.05 mm.

The technology of the MINIBEND press brake

The stroke can be adjusted by handwheel or programmed using a SIEMENS PLC control. The SIEMENS control system is an open control system that allows several machine functions to be programmed so that it can be used for moulding, bending, straightening, tube bending, punching, cutting, etc., depending on the application.

Our expertise gained over decades lies in the development of special bending and punching tools, which are used on our bending presses. Whether in the production of machines with special tools for the aviation industry, the manufacture of handles in the furniture industry, the production of copper welding gun electrodes, specially shaped assembly irons for tunnelling or clamping rings for pressure cookers, special straightening systems for profiles in vehicle construction... an almost inexhaustible field of applications lies behind or ahead of us.

The small bending press from INDUMASCH with a pressure capacity of 20 tonnes and a stroke of 200 mm is characterised by its compact design. The machine table has a clear, open design and is therefore suitable for the installation of standard or special tools.

Whether for bending with an optionally controlled side stop as a small press brake or as a drive element for special tools for special forming or punching of all metals and non-metals.

Technical data

- 200 kN capacity

- Bending capacity: e.g. 150 x 10 mm sheet steel

- 200 mm stroke

- the position of the working cylinder is behind the work table - thus free bending area

Machine dimensions L 690 x W 520 mm - Maschinenmaße L 690 x B 520 mm

- 950 mm Working height

- 500 kg Machine weight

- 4.0 Kw Hydraulic drive

- 400 V, 50 Hz Electrical connection

Video: Indumasch universal bending machines

Bending machine and application training

The decision in favour of an INDUMASCH machine is a decision in favour of state-of-the-art technology and high quality.

To ensure that all the advantages and technical possibilities of the bending machines can be utilised quickly and to their full extent, the operators are trained to become real experts within a very short time as part of professional training courses - so nothing stands in the way of efficient work with optimum production results!

Both in-house training courses, which are carried out directly on the new machine, and training courses in the INDUMASCH test workshop can be organised. The latter is ideal for training employees in advance so that they are already familiar with the INDUMASCH solution on the day of commissioning.

IMPORTANT for existing customers: New projects or staff changes mean a lack/loss of KNOW-HOW. This costs productivity and efficiency is lost. Production results leave a lot to be desired. DON'T LET IT GET THIS FAR. Request a free and non-binding retraining offer for your employees now. Our bending experts will keep you up to date.